Kolkata, India ![]() GST No.19BCBPR7038D1ZJ

GST No.19BCBPR7038D1ZJ

Call us now

08045802757Electric Control Panel

90000 INR/Unit

Minimum Order Quantity : 20 Units

Delivery Time : 10 Days

Surface Finish Painted

Material Metal

Base Material Metal Base

Supply Ability 5500 Per Month

Payment Terms Cash Advance (CA)

Main Domestic Market All India

About this product

An enclosure that houses electrical parts and control devices used to monitor and manage various electrical systems and equipment is known as an electric control panel, also known as an electrical control panel or switchgear panel. It acts as a focal point for managing and safeguarding electrical circuits in commercial, industrial, and residential settings.

Here are some significant characteristics and elements often included in an electric control panel:

1. To give the internal components physical protection, the control panel is often enclosed in a metal or plastic enclosure. The enclosure could feature a hinged door for simple access and be IP (Ingress Protection) or NEMA (National Electrical Manufacturers Association) rated for environmental situations.

2. Circuit breakers and fuses are crucial parts of a control panel because they shield electrical circuits from short circuits and overcurrent situations. By stopping the flow of current as necessary, they assist in avoiding equipment damage and electrical risks.

3. Relays and Contactors: Relays and contactors are electromechanical switches and controllers for electrical circuits. Within the control panel, they are frequently utilised to regulate motors, lighting setups, and other loads.

4. Control Devices: The front surface of the control panel is equipped with control devices such pushbuttons, switches, selector switches, and pilot lights. Operators can start, halt, and control a variety of electrical system or equipment functions with these devices.

5. Terminal Blocks: Within the control panel, terminal blocks offer points for connecting electrical wires or cables. They make wire termination simple and orderly, which makes wiring and maintenance easier.

6. Timer, relay, programmable logic controller (PLC), and other devices used for automation and process control are examples of control circuit components. For the purpose of managing the operation of machinery or processes, they offer logic and timing functions.

7. Busbars, power supply units, transformers, and distribution blocks are just a few examples of the power distribution parts that could be found in the control panel. These parts distribute electricity to different control panel circuits and, if necessary, can step down voltage levels.

8. Wiring and Cable Management: To arrange and route the electrical wires and cables, the control panel has wiring and cable management systems. This guarantees orderliness, security, and ease of upkeep.

9. Monitoring and Instrumentation: Some control panels include monitoring and instrumentation components like metres, indicators, and displays to keep an eye on variables like voltage, current, temperature, or pressure. The performance of the system may be monitored by operators thanks to these devices' real-time data.

10. Safety and Protection: To ensure safe operation and prevent unauthorised access to live electrical components, control panels may contain safety features like emergency stop buttons, interlocks, and lockable enclosures.

Electric control panels are made specifically for the electrical system or piece of machinery they are used to regulate. Small, straightforward panels for fundamental control operations can be found alongside huge, intricate panels for sophisticated automation and process control applications. To ensure safety and compliance, control panel design, installation, and maintenance should be carried out in line with applicable electrical regulations and standards.

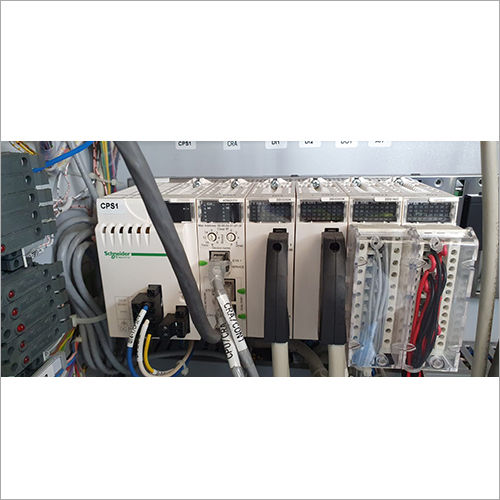

Electric PLC Panel

100000 INR/Unit

Minimum Order Quantity : 20 Units

Delivery Time : 10 Days

Surface Finish Painted

Material Metal

Base Material Metal Base

Supply Ability 5500 Per Month

Payment Terms Cash Advance (CA)

Main Domestic Market All India

About this product

An electric PLC panel is a housing for a programmable logic controller (PLC) and related industrial automation components. It consists of the PLC, power supply, communication and I/O modules, wiring, terminal blocks, and safety equipment. Centralised control, monitoring, and communication between the PLC and external devices are made possible by the panel. It guarantees the reliable and effective operation of equipment and procedures in industrial environments. In addition to offering physical protection, the enclosure may also have features like cable management, environmental resistance, and cooling systems. In industrial automation systems, the PLC panel is essential for automating procedures, increasing productivity, and enabling smooth component integration.

Industrial PLC Panel

90000 INR/Unit

Minimum Order Quantity : 20 Units

Delivery Time : 10 Days

Surface Finish Painted

Material Metal

Base Material Metal Base

Supply Ability 5500 Per Month

Payment Terms Cash Advance (CA)

Main Domestic Market All India

About this product

An enclosure that stores the parts and wiring required for the operation and control of a programmable logic controller in an industrial context is known as an industrial PLC (Programmable Logic Controller) Panel, also known as a PLC Control Panel or a PLC Cabinet. PLCs are frequently used in industrial automation to manage and keep an eye on machinery, equipment, and processes.

The following are some essential characteristics and parts often found in an industrial PLC panel:

1. PLC: The programmable logic controller is the brains of the panel. The PLC is a digital computer with industrial applications that can communicate with different input/output (I/O) devices and execute control logic.

2. Power supply: The panel has a power supply unit that changes the electrical power coming in to the voltage and current needed to run the PLC and other components. It guarantees dependable and steady power distribution throughout the panel.

3. The interface between the PLC and the external devices or sensors is provided by input/output modules. While output modules deliver signals to control actuators, motors, valves, and other equipment, input modules receive signals from sensors, switches, and other devices.

4. PLCs can connect with other devices such as human-machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, remote I/O devices, or other PLCs thanks to communication modules. Modbus, Profibus, DeviceNet, Ethernet/IP, and other common communication protocols are also used.

5. Wiring and Terminal Blocks: Within the panel, the wiring is organised and connected using terminal blocks. Installation and maintenance are facilitated by the termination points for the numerous electrical connections that they provide, which are safe and easy to access.

6. HMI/Operator Interface: To visualise and communicate with the PLC system, the panel may have an operator interface or human-machine interface (HMI) device. Operators can view system status, control parameters, and monitor process data thanks to the HMI.

7. Circuit breakers and other protection mechanisms: The panel is equipped with circuit breakers, fuses, and other safety features to guard against overcurrent, short circuits, and electrical problems. They contribute to ensuring the apparatus and system's safety.

8. Wiring Ducts and Cable Management: To route and arrange the wiring and cables inside the panel, cable management systems and wiring ducts are employed. They lessen electromagnetic interference, make maintenance and troubleshooting easier, and assist maintain a neat and usable layout.

9. Cooling and ventilation may be necessary in some circumstances for industrial PLC panels to dissipate heat produced by the components. This guarantees optimal operating temperatures and increases the equipment's longevity.

10. The panel is often housed in an enclosure that is intended to shield the components from environmental hazards like dust, moisture, and physical damage. An enclosure's Ingress Protection (IP) rating may be tailored to denote how resistant it is to environmental factors.

Industrial PLC panels are made to order to meet the demands of the process or automation system they are controlling. They are essential to industrial automation because they provide centralised control, monitoring, and data gathering. For the industrial system to run reliably and effectively, proper PLC panel design, installation, and maintenance are required.

PLC Panel

100000 INR/Unit

Minimum Order Quantity : 20 Units

Delivery Time : 10 Days

Surface Finish Painted

Material Metal

Base Material Metal Base

Supply Ability 5500 Per Month

Payment Terms Cash Advance (CA)

Main Domestic Market All India

About this product

Explore Additional Categories

Contact Us

Our Products

Our Products